Canada’s oil sands are an important source of energy and economic activity, but the bitumen that is extracted there takes a lot of processing and cleaning before it can be transported to refineries to be converted into usable oil.

The first step of that process is “frothing,” in which the raw bitumen is mixed with water and air bubbles are forced through it to create a frothy, bubbly layer of somewhat cleaner bitumen that leaves much of the sand behind. But that froth layer still has some sand and water in it.

Liuyin Xia, a mineral processing professor at the University of Alberta, and her colleagues are looking for ways to create a cleaner froth containing less sand. Their work is published in the journal Cleaner Engineering and Technology.

“We want a high-quality froth with less water and solids mixed in with it, because those solids have to be washed out with solvents further downstream,” she says.

First, they needed to understand how the solids end up in the froth—something that, despite 40 years of bitumen processing, nobody has really figured out yet. Cracking this code, says Xia, is critical for developing new techniques for producing high-quality bitumen.

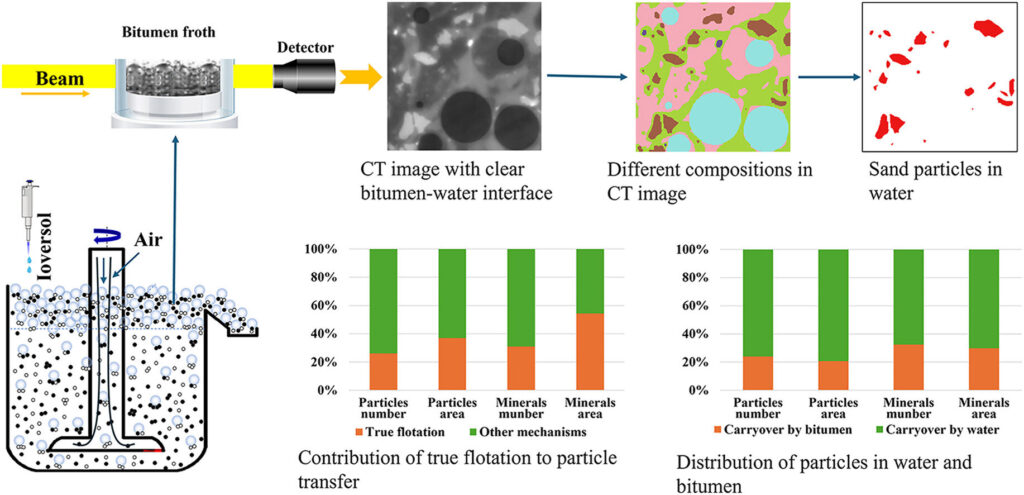

She and her team used the powerful X-ray beamlines of the Canadian Light Source (CLS) at the University of Saskatchewan to observe the sand that moves upwards with the froth.

“The froth is dynamic and can change in seconds,” says Xia. “The CLS beamlines make it possible to capture images of the froth in real time at micrometer resolution.”

They found that about 40% of the solids in the froth were attached to air bubbles, and that heavier minerals like rutile that stick to oil better are more likely to do this than sand. They also saw that most of the solids in the liquid part of the froth were carried by the water rather than the oil.

“When we know these are the reasons behind the solids carrying over, we can develop a more efficient and environmentally friendly oil sands processing technology,” she says.

Xia says their findings suggest reducing the amount of water carried with the bitumen should be a straightforward way to decrease unwanted solids, to achieve a higher-quality froth.

More information:

Hanyu Zhang et al, Synchrotron X-ray imaging study on the mechanism of solids transfer to bitumen froth during oil sands flotation 2: Water entrainment, Cleaner Engineering and Technology (2025). DOI: 10.1016/j.clet.2025.101036

Citation:

X-ray imaging point way toward cleaner oil sands processing (2025, September 11)

retrieved 12 September 2025

from https://techxplore.com/news/2025-09-ray-imaging-cleaner-oil-sands.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.