University of Wisconsin–Madison mechanical engineers have developed a comprehensive framework that accelerates improvements to shock-absorbing foam materials.

The materials have an array of uses ranging from sports or military helmet liners to struts that cushion a spacecraft landing.

“We’ve developed a novel design framework to help designers create a shock-absorbing material of a specific geometry that does exactly what they want it to do without adding weight or extra volume,” says Ramathasan Thevamaran, an associate professor of mechanical engineering at UW–Madison who led the research.

“It allows designers to customize the material for the best performance, tailored to diverse applications, without going through lots of experimental trial and error.”

The advance also opens a new perspective on how to approach the design of protective materials by challenging conventional wisdom.

Traditionally, the goal has been to design a shock-absorbing material with mechanical properties that allow it to maintain a constant stress plateau. Designers typically use an iterative process that focuses on optimizing the mechanical properties without factoring in the thickness and area of the foam pad used in applications.

The UW–Madison researchers took a different approach. They investigated the thickness and area of foam pads in conjunction with mechanical properties. To their surprise, they discovered that, in certain impact scenarios, foams exhibiting a different kind of behavior—a nonlinear stress-strain response—can outperform foams that hold the stress level constant.

“This work shows foams that have been traditionally considered as ‘ideal absorbers’ aren’t always the best,” Thevamaran says. “We show foams with a nonlinear response can in fact offer a broader design space, especially when a compact pad design is required. Notably, these findings are very general and applicable to a wide range of material systems, including metamaterials.”

The team detailed its findings in a paper published August 4, 2025, in the journal Nature Communications.

The researchers’ new framework provides design criteria for maximizing a material’s energy absorption based on several variables. The inputs include the foam pad’s thickness and area and the material properties. The researchers also specify the thresholds for acceleration and stress for a given impact.

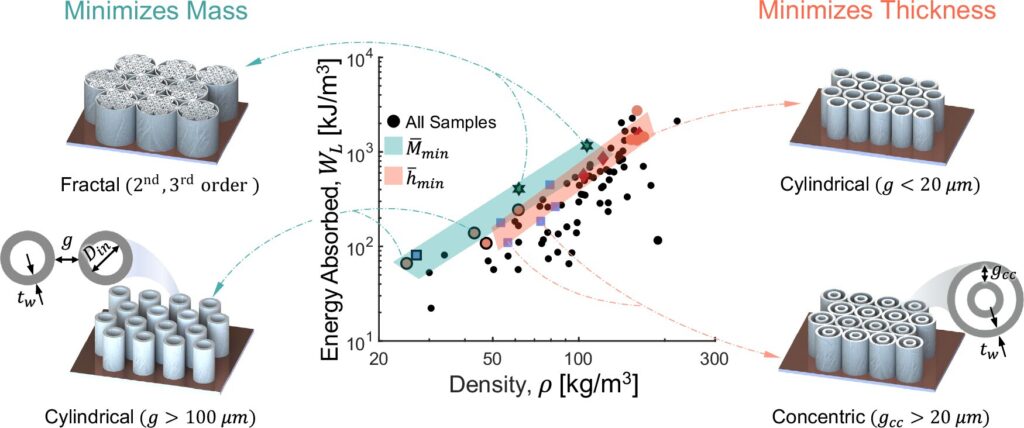

With this information, the framework produces a design map for the desired material. Designers can use this map to easily customize the material—for example, they can optimize for minimal thickness or lighter weight, or both.

To demonstrate the effectiveness of their framework, the researchers used it to achieve optimal protective properties in architected vertically aligned carbon nanotube foams they have been developing.

The researchers have made their framework freely available online.

More information:

Abhishek Gupta et al, Embracing nonlinearity and geometry: a dimensional analysis guided design of shock absorbing materials, Nature Communications (2025). DOI: 10.1038/s41467-025-60300-8

Citation:

Accelerated design framework makes it easier to create custom shock-absorbing materials (2025, August 18)

retrieved 19 August 2025

from https://techxplore.com/news/2025-08-framework-easier-custom-absorbing-materials.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.