In a potential step toward sending small spacecraft to the stars, researchers have developed an ultra-thin, ultra-reflective membrane designed to ride a column of laser light to incredible speeds.

Since its launch in 1977, NASA’s Voyager 1 spacecraft has traveled over 15 billion miles into deep space. That’s a long way—but it’s not even 1% of the distance to Alpha Centauri, the nearest star to the sun. If humans are going to send ships to the stars, space travel will have to get a lot faster.

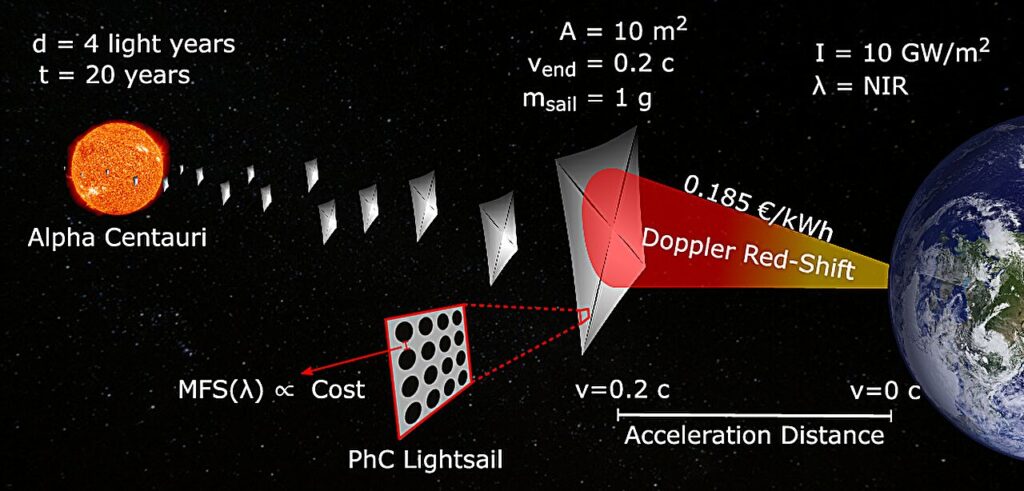

One promising way to pick up that kind of speed is a “lightsail“—a thin, reflective membrane that can be pushed by light much the same way that wind pushes a sailboat. Lightsails have the potential to reduce flight time to nearby stars from several thousand years using current propulsion systems to perhaps just a decade or two.

Now, a team of researchers from Brown University and Delft University of Technology (TU Delft) in the Netherlands has developed a new way of designing and fabricating ultra-thin, ultra-reflective membranes for lightsails.

In a study published in Nature Communications, the researchers describe a lightsail membrane that’s 60 millimeters (about 2.4 inches) wide by 60 millimeters long, but with a thickness of just 200 nanometers—a tiny fraction of a human hair.

The surface is intricately patterned with billions of nanoscale holes, which help to reduce the material’s weight and increase its reflectivity, giving it more acceleration potential.

“This work was a joint effort between theorists at Brown University and experimentalists at TU Delft, making it possible to design, fabricate and test a highly reflective lightsail with the largest aspect ratio recorded to date,” said Miguel Bessa, an associate professor in Brown’s School of Engineering who co-led the research with Richard Norte, an associate professor at TU Delft.

“The experimental breakthrough of Richard’s team proves their fabrication process is scalable to the dimensions needed for interstellar travel and can be done in a cost-effective manner. Simultaneously, my team is very enthusiastic to see the essential role of our latest optimization method guided by machine learning in solving such an interesting and difficult engineering problem.”

The research is a significant step toward realizing goals like those of the Starshot Breakthrough Initiative, founded by entrepreneur Yuri Milner and the late physicist Stephen Hawking.

The goal is to use ground-based lasers to power hundreds of meter-scale lightsails carrying microchip-sized spacecraft. This new lightsail design could be scaled up to meter scale fairly easily, the researchers say, and with a manageable price tag.

For their design, the team used single-layer silicon nitride, a lightweight and high-strength material that’s well-suited for lightsail design. The researchers then worked to maximize its reflectivity while minimizing its weight.

The reflectivity of the surface determines how much light pressure is created behind the sail, which in turn determines how fast it can accelerate. At the same time, a lighter material requires less force to accelerate, so less mass equals more speed.

The optimization process involved designing a pattern of nanoscale holes—billions of them across the material’s surface with diameters smaller than the wavelength of light. Bessa’s team, including Brown Ph.D. student Shunyu Yin, used a new artificial intelligence method they developed to optimize the shape and placement of the holes for increased reflectivity and decreased weight.

Once they had an optimized design, a team led by Norte at TU Delft went to work fabricating it in the lab.

“We have developed a new gas-based etch that allows us to delicately remove the material under the sails, leaving only the sail,” Norte said. “If the sails break, it’s most likely during manufacturing. Once the sails are suspended, they are actually quite robust. These techniques have been uniquely developed at TU Delft.”

Fabricating this design with traditional methods would have been expensive and taken as long as 15 years, the researchers say. But using Norte’s techniques, fabrication took about a day and is thousands of times less expensive.

The result is a membrane that the researchers believe has the highest aspect ratio—centimeter-scale length but with nanoscale thickness—of any lightsail design to date. The researchers hope that their methods will not only help humans reach the stars, but also push the limits of nanoscale engineering.

“The new machine learning and optimization techniques we used here are very general,” Bessa said. “We could use them to create lots of different things for different purposes. This is really just the beginning. We might be on the verge of solving engineering problems that have remained unsolvable up to now.”

More information:

Lucas Norder et al, Pentagonal photonic crystal mirrors: scalable lightsails with enhanced acceleration via neural topology optimization, Nature Communications (2025). DOI: 10.1038/s41467-025-57749-y

Citation:

Researchers develop new design and fabrication method to make lightsails for interstellar travel (2025, March 30)

retrieved 31 March 2025

from https://techxplore.com/news/2025-03-fabrication-method-lightsails-interstellar.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.